To Toast or not to Toast?

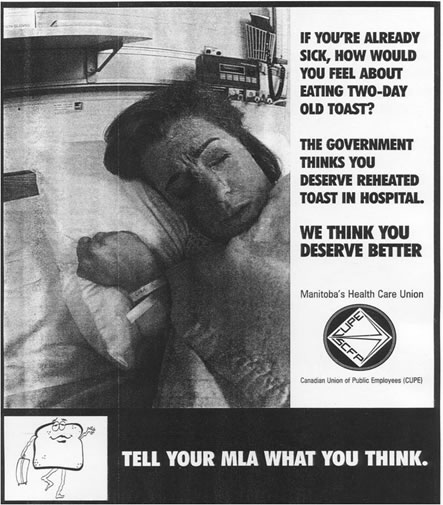

In the early 1990’s a meal delivery system company said to its clients that they could re-heat toast using their retherm (regeneration) tray meal cart system. The client trusted the company. The result was Canada wide press coverage of a War Veteran holding a piece of soggy toast in his hospital bed. From that point forward, toast was forever connected to the modern day advanced meal delivery system in hospitals. What no one truly understood at the time was that the meal delivery system used to re-heat the toast was a conduction system and that system was not suited to do the task at all. The supplier of that system should never have suggested it.

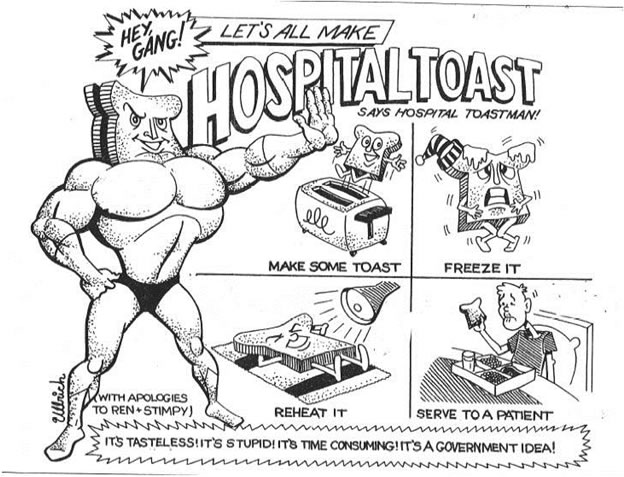

When convected meal delivery systems entered the market in the mid 1990’s in full force, the re-heating of toast started to gain momentum as results were very good. Convected tray retherm systems were quite capable of gently warming pre-prepared toast back to a good serving temperature while maintaining crispiness and a fresh appeal. But the past caught up and the spectre of poor soggy toast came to the forefront once again when Winnipeg implemented a regionalised meal delivery system in 1998. Even if the toast was pretty good, the press played on the ghost of toasts gone by and we even saw the emergence of a Toast Mascot for the Union as well as numerous cartoon articles and press commentary.

Okay, so we know that toast for patients or a resident is a sensitive issue. It is a comfort food and not to be served cold or soggy. When a facility uses a meal tray preparation like a just in time method (the food is plated and presented to the client within minutes of tray preparation, i.e. often referred to as a hot-line) the toast can be prepared and served quickly. It may be a little cold but it is made just before service and so it is perceived as fresh. Then a facility decides to adopt a cold tray assembly process where trays are prepared in advance of the meal times and then reheated close to service. The question is then; can toast be reheated successfully in this process? The answer is yes. Do all users of advanced cold tray assembly equipment provide toast using the retherm system to re-heat it? The answer is no, not everyone does.

Re-heating toast in a retherm system is an art. It is not easy. These, coupled with the historical public outcries around cold plating initiatives, have made a number of operators shy away from giving it a try. But it can work, given control over certain variables and the right approach. Making it work is similar to knowing how to make a crème brulée. To make a good crème brulée, one employs a technique and follows a recipe. If the technique is incorrect or the recipe is not exact, the result will be a disaster. Similar concerns can be said about toast in retherm systems. So here are a few hints and comments about the proper technique of preparing and serving toast in a retherm based meal delivery system.

- It is best to use the freshest bread possible if you are to make the toast yourself. The bread should be as thick as possible as well. Texas Style sliced bread is a good start but often this style bread comes with a large amount of crust. The least amount of crust gives the best results. For the optimum result use a bread slice with the crusts removed.

- When preparing the toast, keep it covered after preparation as much as possible to retain the moisture in the bread. So, when you are toasting 1-4 slices at a time, keep the prepared toast pieces to the side well covered. In other words, don’t wait for the batch to be done before you start covering the toast.

- Yes, you can freeze the toast once it has been made or even buy pre-made frozen toast but be warned that freezing does remove moisture

- It is best to prepare the toast as close to cold plating or bulk cold panning as possible and so, you can prepare your toast in the evening for the next day but keep it well covered. You’re a star if you can prepare the toast in the morning and let it sit at room temperature at the trayline well covered. This will be the freshest and have the most moisture.

- At the trayline, keep the toast well covered.

- You can butter the toast after it has cooled down and hold it as such but often in Acute Care settings clinical dietitians have a problem with this process due to the added calories and that this product may not be acceptable for all diet types and patients will allergies. In long term care, buttering the toast ahead of re-heating can be beneficial and will increase the moisture, produce a nice aroma and eliminate the need to put the butter or marg on the table/tray.

- Do not try and retherm (regenerate) the toast in a conduction retherm system. You will be asking for trouble. Use a convection style retherm system to re-heat toast.

- For the best result, place the toast in a foil bag and fold down the top edges so there is a tight seal. This practice does retain moisture and helps promote a true toast texture, however, this does become an extra step and extra packaging that costs money. Many operators prefer the outcome using a bag and invest the operational time and added costs to get a quality outcome.

- For best results heat the toast on a ceramic that has a dome lid. If the toast is in the bag, the bag can be placed on the plate along with other items such as eggs and bacon etc. If one does not use a bag, then put the toast on the plate and cover with the lid but try and avoid combining the toast with eggs such as scrambled eggs – in this case use a bag or a separate plate if possible.

- When serving the plate to the patient, for best results (and this is the secret) do not remove the lid. Let the patient remove the lid when they are ready to eat the food. As soon as the lid is removed, the quality of the toast suffers and it gets hard, especially the crust.

We have seen a completely different technique that worked very well. The operator held their cold tray line and put no toast on the tray at that time. The food trays were rethermed and while that took place they made toast and held the toast covered at room temperature. They bagged the toast and then just after the retherm cycle ended and before the tray rack left the central retherm galley, they lifted the lids of the trays that needed toast and placed the toast bag on the plate and put the lid back on. While the tray rack was transported to the patient floor, the heat from the plate and lid simply re-heated the toast slice(s). It was a quality result. The operator took a lot of care to prepare the toast in the best way…a dedicated toaster!

Burlodge has developed a recipe for preparing toast for cold plating. This was done with the assistance of 30plus operators at a user meeting and shows the steps that need to be taken to prepare toast that does not fall short of what toast should be.

TOAST RECIPE

• Set toaster at _____ to preheat

• Prepare required tools

- Pan GN 1/1, 4” depth

- Bread knife

- Thick bread made from milk, egg white and eggs

- Large Saran wrap

• Toast bread slightly

• Preferably do not cut bread, if you do, cut in ½ :

- Cut 2 slices at a time

- Always use a bread knife

- Slice by a saw movement – do not squashed bread

• Put in pan

• Cover pan immediately with Saran Wrap to avoid dryness – make sure the pan is well sealed

• Keep at room temperature, do not refrigerate

• Do not stock for more than 1 day

• During beltline, make sure the pan is covered to keep humidity – we recommend to uncover ¼ of the pan at the time.

Note: I loaf of bread = 12 slices

VERY IMPORTANT: during all the process, make sure to keep humidity (at time of toast preparation, in storage and at beltline)