An early memory I hold close is when I first realized the art and impact of the personal touch at meal service. It happened in London England when I was 8 years old. We were visiting from Canada to attend my Great Grandmother’s 100th birthday celebration. On our way to Nottingham we stayed in London for a couple of days and one night enjoyed a wonderful meal at a swanky hotel. At the close of the meal, a smartly dressed waiter approached with a trolley full of wondrous treats. I saw cakes, pastries, cheeses, and a bowl of fresh raspberries. It was then I became a member of the ‘Fresh Raspberries and Cream (with a sprinkle of sugar) Club’. I can still see the raspberries fall from the spoon into the clean white bowl, and the cream fold over the red fruit as it poured slowly from the silver jug. I can still hear the sugar sprinkle over top to finish the preparation. That taste, that moment, seemed so foreign to me at that time in my life, yet so very comforting. It made me feel very special – like a prince. It was the final part of that meal and the positive sensations have stayed with me for over 40 years.

I went to University in my 20’s and learned about the primacy and recency effect. The primacy effect means that people tend to remember the first information presented about something better than information presented later. However, there is something that trumps the primacy effect: the recency effect means that people tend to remember the most recent information presented about a product above all else. So we can safely bring all of this to familiar terms – first and last impressions with the last impressions being the most powerful of the two and truly everlasting, just like my bowl of raspberries and cream.

I learned more about food when I began my career as an hotelier and restaurateur. I worked at a hotel that had a very expensive restaurant with an amazing menu. They specialized in French Service where foods would be ‘finished’ at the table. This is where I saw the dessert trolley again only this time they called it a gueridon. On this most elegant trolley appeared a selection of desserts including pastries and cakes made by the in-house pastry chef as well as a fresh fruit salad featuring seasonal fruit. The dessert trolley included the same items every night. It was easy for the servers to set it up and keep it clean and tidy. Production was simplified as all the pastry chef had to do was to make sure he had the kitchen properly stocked in advance of service. He made the same things each day and consistency was always guaranteed. So you combine consistently excellent fresh desserts alongside personal table service and you get a powerful everlasting impression that equaled high customer satisfaction and perceived value. The perfect combination – as good as raspberries and cream could ever be.

And so, now I am in my later part of my career and I provide equipment solutions to healthcare food service clients. Over 40% of my clients offer some form of table or dining room service while the balance provide bedside tray service. I visit these locations often. I have to say that the people that work in the food service industry are amazing and very hard working. They are open every day of every year and serve three square meals each day and often the meals are customized to meet a variety of diets that would boggle the mind. It is truly amazing. So don’t take what I am about to say as criticism – rather see it as an observation of an opportunity….Where is the raspberries and cream?

I mean, why do we always see a menu at a Long Term Care Home that shows a 28 day cycle and today’s lunch has Fruit Cup at dessert while dinner there is Apple Pie. And thanks to the 28 day menu cycle, the fruit cup does not appear again on the menu until 10 days later and the Apple Pie is not offered until 22 days later. Why not offer the fruit cup and the Apple Pie every day? Why not offer a selection of desserts on a trolley every day? This trolley can be wheeled through the dining room and clients can look and chose right there at their table. They may even decide they want a bit more orange segments in their fruit salad tonight. Mr. Jones can have Apple Pie three nights in a row if he wants to. It begs the question doesn’t it– ‘do we have a cyclical dessert menu at home, or do we just grab what we want when we want it?’ Giving the residents back a sense of control will be a huge accomplishment and only goes to help improve pride, increased sense of self-worth, and positive emotion. These feelings carry over in-between meals to aid in environmental improvements as morale in the home will improve. The power of a happy resident also translates into happier and self-actualized staff as well as a proud community. The efficiency of preparing the same dessert items every meal should reduce waste and allow for greater economies and menu flexibility. It all sounds like a win win. An everlasting positive impression awaits. All we need now is for someone to stand up and give it a try! Why not start with some fresh raspberries, a dribble of cream and a sprinkle of sugar.

We’ve all heard the phrase ‘the customer is always right.’ It doesn’t seem to matter what line of work you find yourself in, when it comes to service, ‘the customer is always right.’ Down the road, in my career, I heard another mantra and it was, ‘the answer is yes; now what is the question?’ The premise of this mantra is the same as the first: i.e. great customer service.

I often try to find new ways to explain great customer service to my clients, students, and industry peers. There are many customer service gurus who suggest daily reminders or cheery pep talks but while sitting with my son one night I discovered a new way to illuminate customer service. It all started with Harold and the Purple Crayon.

As I put my son to bed that night he asked me to read him a story about a young boy named Harold. Harold is a vivacious little guy, who instead of going to sleep decides to embark on a wondrous adventure with his purple crayon. I do try to balance work and home but that night I could not help but think of my company as I read about Harold. Using his crayon, and imagination, Harold draws himself into a journey in which he becomes lost yet finally locates the moon which helped guide him back to his bedroom. Like Harold, many companies find themselves on a journey and sometimes lost in difficult situations. Harold uses awareness and creativity to navigate his quest. He is in full control of his direction but like many good companies, sometimes he has to suddenly adjust and navigate through a challenging moment like falling off a mountain. Even still, he creates opportunities for himself such as drawing a balloon to bring him to safety or drawing an assortment of pies, so he may have a picnic.

As I read, I noticed in many ways, this story directly reflects the journey of most businesses. There are times when companies need to be creative to overcome difficult situations and being aware of market changes is vital to surviving. As well, a good company does not wait for opportunities, but like Harold creates them. The most important message found in the story was that companies must follow their clients the way Harold followed the moon.

Every day I overcome challenges and create opportunities, but without our clients guiding us I have no mission and no way of framing my goals. Every company should acknowledge that the client is the centre and sole purpose of a business’s existence.

At Burlodge we are motivated to help others. I look for staff who are passionate and are driven by opportunities to do so. Our clients are food service managers and line staff however, we believe their patients are just as important. When we build and create, we are motivated to make a positive difference to everyone’s lives. Providing great customer service is extremely rewarding and should be the guiding light for all companies through their adventures.

Some might say that our competitors are feeling the heat because Burlodge has created an unbeatable line of mobile hot food servers. As many of our customers have grown accustomed, here’s another line from Burlodge that earns its reputation by combining outstanding design, durability, functionality and value. Whichever model appeals to your needs, each of our hot food servers is ready to meet the demands of today’s operations.

Burlodge hot food servers are built of stainless steel 18/10 [AISI 304] Scotch Brite Finish and feature ergonomic push handles and a robust built-in bumper. Double-wall construction and isothermic insulation to minimize heat dispersion combines with non-flammable, chemically neutral insulation to ensure optimum safety and efficiency. A drain tap for water is located in the upper tank(s), which includes a moulded upper section with a reservoir to prevent any liquid leakage, while the lower section has an easily accessible retractable door. The moulded control panel is effortless to use and is designed to ensure quick cleaning. This is all mounted on four 160mm/6.3” polyurethane rubber wheels – two fixed and two swivel wheels with a pedal brake.

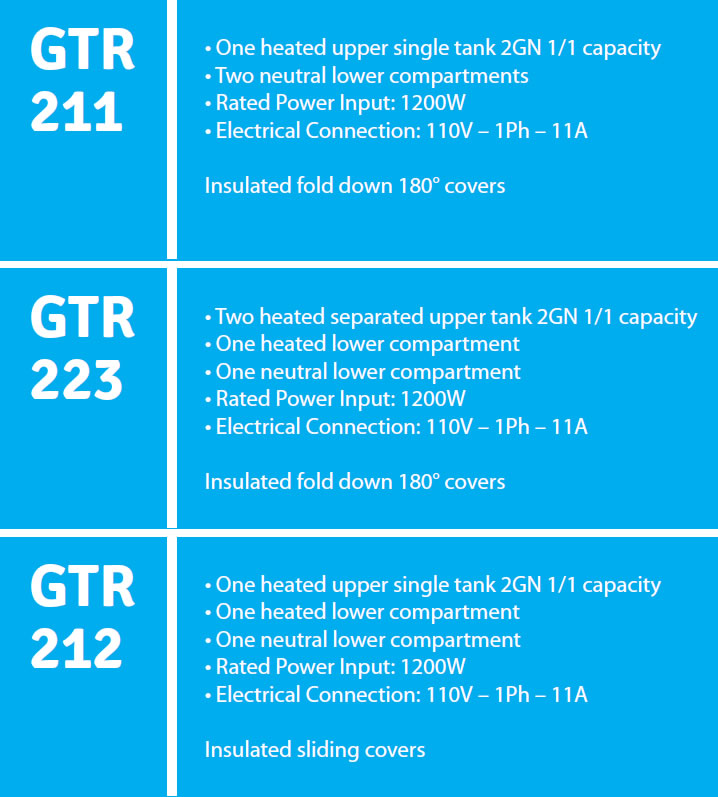

The Burlodge GTR Series of mobile serveries:

This is professional calibre equipment that food service operations need in today’s market.

Burlodge Canada LTD is proud to announce the opening of a new test kitchen at its Head Office in Brampton, Ontario. The company renovated a space adjacent to its expansive showroom during the summer of 2013 to create a working and flexible kitchen space so it can continue its development of fresh and local recipes for healthcare. But there was more to the idea than just cooking fresh and local foods and testing them in Burlodge Equipment…much more. The new space will be used to hold training videos as well as host meetings for outside groups who want to hold training sessions on particular branded foods. Food manufacturers will be invited to use the cuisine centre to test their food products in Burlodge equipment. The cuisine centre will also provide an excellent back-drop for the continuation of Burlodge’s training sessions for Community Colleges and Universities.

What Burlodge does differently goes far beyond designing and manufacturing high performance equipment. Yes, the company has garnered an excellent standing among institutional food service professionals for its extensive range of products that accommodate hot-line, cook-serve and cook-chill applications. However, Burlodge further distinguish itself by partnering with key industry food suppliers and distributors to assist in every way possible to help them continuously improve their products not to mention introduce new products. With the new test kitchen, Burlodge enhances that support with considerable integrity.

Burlodge also provides the test kitchen to its clients for their use or to attend free educational seminars about the best ways to use Burlodge equipment. Regardless of the size of their operation, Burlodg e aims to optimize each client’s resources and streamline their food service logistics so they get the most out of our machinery, as well as their staff.

With the untold challenges of managing food service operations, Burlodge complements its diverse product mix with a staff largely comprised of former food service professionals, including chefs from healthcare, dietitians, catering managers and more. Who better to address the issues and devise the solutions than those professionals who have earned their way on the front line of the industry?

In my experience, Psychiatric Patients are seldom served appropriately. The default position is a Trayed Meal, often large or double portions (due to medicine they are on driving a need to eat or the medical team wanting to satiate to subdue). However, a trayed meal does not help drive a therapeutic milieu akin to quality mental health care. In many cases, I have been personally involved with challenging the status quo and implementing bulk style dining for psychiatric patients in dining rooms with great success. In the same breath however, I note numerous facilities who have attempted a conversion from a trayed meal to bulk style dining only to retreat when Nursing gets fed-up and loses the motivation for change or Nursing is resistant because no one involved them in the change process to begin with.

Changing a meal service style is very difficult. The challenges are compounded in a mental health setting. Having a strong food service manager in place who communicates with Mental Health Staff in advance of making any changes is critical. The facility will have to invest time and money training food service staff on understanding Mental Health and verbal diffusion skills so that they can feel confident in front of Patients if they are to serve meals using a bulk meal service cart.

There are facilities specific to Mental Health and there are hospitals that have some dedicated Mental Health wards. In the case of the 100% Psychiatric Hospital there are more than likely some areas of care that cannot support a Bulk Dining Program (i.e. family style dining in a dining room using a Multigen and patient coming up to the cart and making choices). These areas may be places like high security areas and Acute Units (short stay) and in these case it would be appropriate for a trayed meal to be served (hot line or cook chill preparation style). In other areas however, we may see Chronic Care or Geriatric specialties of care where longer stays prevail and thus menu fatigue is always a factor, therefore, having a family style dining concept in these units allows patients a choice at time meal service and this will truly enhance the therapy they are getting. If a hospital has only a couple Mental Health wards, there is nothing to stop them from a implementing a similar ward based dining room style bulk meal service.

When bulk meal service is adopted, there are so many flexible ideas that can be reviewed to enhance the dining experience. For example, at Breakfast why not consider a buffet self-service breakfast approach with extended dining times. This would give patients considerable choice and a sense of control at the moment of dining. Secondly, the extended dining time would make things a little easier for nursing who have to get everyone up and ready for breakfast each morning. They may appreciate added flexibility. The meal plan would provide standard items each day and may even have a hot option available for everyone (cereal or eggs and bacon) in bulk. If items are standard each day then the preparation and set-up is easy for foodservice staff. It could easily resemble a bed and breakfast style set up one would see while traveling. It would encourage family style dining and help with the overall therapy and sense of normalcy.

The ideas are endless. With family style dining one can even encourage staff on the units to sit with patients during meal times as part of their therapy. It is highly suggested that the dining lounges are improved aesthetically (a little paint and color will go a long way, as will some paper table cloths, bread baskets, etc).

The menu can be slightly different than the rest of the house and can either be based on a selection of two entrees each meal or can involve patients to pre- select their entree the day before. Cold meals can be selected at ward level from a ‘soup of the day’ and cold menu of choices (juices, salads, desserts). There is a lot that can be done here and there are some good examples of facilities that have moved to locally assemble meals that you can learn from. All one needs is a little courage, creativity, and charisma to make a difference to those in need of special care.

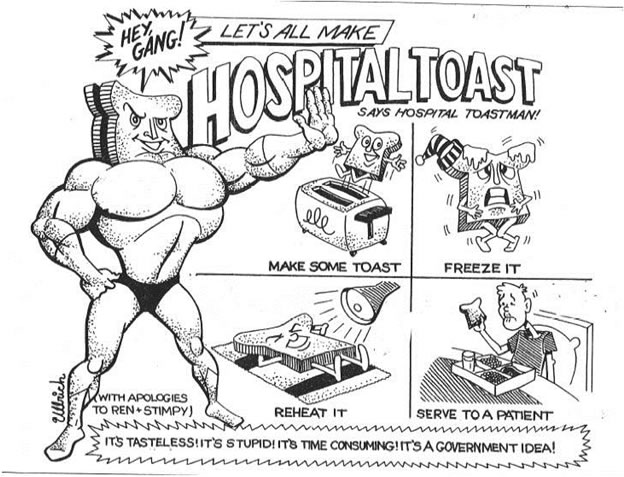

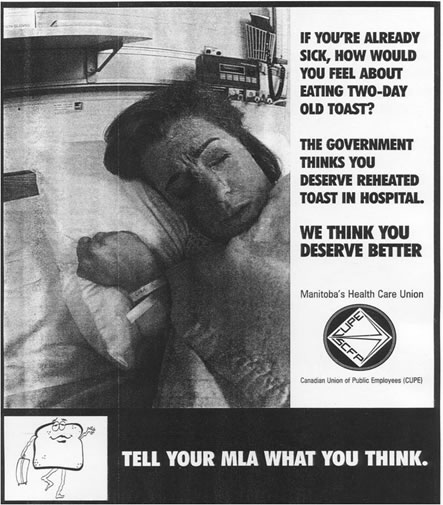

In the early 1990’s a meal delivery system company said to its clients that they could re-heat toast using their retherm (regeneration) tray meal cart system. The client trusted the company. The result was Canada wide press coverage of a War Veteran holding a piece of soggy toast in his hospital bed. From that point forward, toast was forever connected to the modern day advanced meal delivery system in hospitals. What no one truly understood at the time was that the meal delivery system used to re-heat the toast was a conduction system and that system was not suited to do the task at all. The supplier of that system should never have suggested it.

When convected meal delivery systems entered the market in the mid 1990’s in full force, the re-heating of toast started to gain momentum as results were very good. Convected tray retherm systems were quite capable of gently warming pre-prepared toast back to a good serving temperature while maintaining crispiness and a fresh appeal. But the past caught up and the spectre of poor soggy toast came to the forefront once again when Winnipeg implemented a regionalised meal delivery system in 1998. Even if the toast was pretty good, the press played on the ghost of toasts gone by and we even saw the emergence of a Toast Mascot for the Union as well as numerous cartoon articles and press commentary.

Okay, so we know that toast for patients or a resident is a sensitive issue. It is a comfort food and not to be served cold or soggy. When a facility uses a meal tray preparation like a just in time method (the food is plated and presented to the client within minutes of tray preparation, i.e. often referred to as a hot-line) the toast can be prepared and served quickly. It may be a little cold but it is made just before service and so it is perceived as fresh. Then a facility decides to adopt a cold tray assembly process where trays are prepared in advance of the meal times and then reheated close to service. The question is then; can toast be reheated successfully in this process? The answer is yes. Do all users of advanced cold tray assembly equipment provide toast using the retherm system to re-heat it? The answer is no, not everyone does.

Re-heating toast in a retherm system is an art. It is not easy. These, coupled with the historical public outcries around cold plating initiatives, have made a number of operators shy away from giving it a try. But it can work, given control over certain variables and the right approach. Making it work is similar to knowing how to make a crème brulée. To make a good crème brulée, one employs a technique and follows a recipe. If the technique is incorrect or the recipe is not exact, the result will be a disaster. Similar concerns can be said about toast in retherm systems. So here are a few hints and comments about the proper technique of preparing and serving toast in a retherm based meal delivery system.

We have seen a completely different technique that worked very well. The operator held their cold tray line and put no toast on the tray at that time. The food trays were rethermed and while that took place they made toast and held the toast covered at room temperature. They bagged the toast and then just after the retherm cycle ended and before the tray rack left the central retherm galley, they lifted the lids of the trays that needed toast and placed the toast bag on the plate and put the lid back on. While the tray rack was transported to the patient floor, the heat from the plate and lid simply re-heated the toast slice(s). It was a quality result. The operator took a lot of care to prepare the toast in the best way…a dedicated toaster!

Burlodge has developed a recipe for preparing toast for cold plating. This was done with the assistance of 30plus operators at a user meeting and shows the steps that need to be taken to prepare toast that does not fall short of what toast should be.

TOAST RECIPE

• Set toaster at _____ to preheat

• Prepare required tools

• Toast bread slightly

• Preferably do not cut bread, if you do, cut in ½ :

• Put in pan

• Cover pan immediately with Saran Wrap to avoid dryness – make sure the pan is well sealed

• Keep at room temperature, do not refrigerate

• Do not stock for more than 1 day

• During beltline, make sure the pan is covered to keep humidity – we recommend to uncover ¼ of the pan at the time.

Note: I loaf of bread = 12 slices

VERY IMPORTANT: during all the process, make sure to keep humidity (at time of toast preparation, in storage and at beltline)

Conventional Ordering Method – while slowly becoming an archaic method, we do still see cases of passing meal plans ( a daily menu selection sheet) to patients for them or family members to select meal components for breakfast, lunch, dinner. They do this using a sheet of paper with the menu printed on it, a pen, and circle the things they want following strict guidelines as noted on the paper. They often do this about 2 days in advance of the actual menu day they are selecting. Of course, this system has its many disadvantages such as and not limited to:

– poor control as patients may actually not be at the hospital two days after they fill in their sheet

– manual and labor intense system for the diet office

– poor control over diet therapy as many mistakes can happen

– patient forgets what they selected and this can lead to poor satisfaction ratings overall

– high food cost due to waste through poor forecasting methods

– diet changes are manual and thus more labor wasted to track and correct menu plans

This system is often applicable to hot serve locations and can be developed using a long cyclical menu of up to 3 weeks. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day.

Selective Menus but Modernized – the patient selects their meal by using a daily menu planner as above, but the information is then inputted into a computer and the diet office then uses a computer software program such as CBORD or COMPUTRITION to tally and talk to production as well as trayline. Proper tray tickets are printed according to the beltline set up and diet therapy integrity checks are done within the software so that patient selections match diet orders. This system is most common now at facilities that are still hot plating although we do see this at cold plating locations. It is still manually intensive and patients may choose meals the day before so there is still a loss of control by the patient which can impact satisfaction. Menus are often developed in 2 week cycles. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day. We are seeing a small resurgence of the selective menu through the use of technology whereby patients can select what they want during a bedside interview by a diet tech or food service worker who enters selections into a palm device but this is rare at the moment.

Non Selective Menus – here we have the use of a computer software system like mentioned above. The system integrates with the hospital’s ADT System (admission, Discharge, Transfer) and thus keeps tabs on who is in the house and who is not. In addition, the system will connect with the hospital patient record info and inform the dietary department when a diet change has been ordered. The intriguing thing about this system is that it is built on the premise that the patient preferences are determined at admission. Here, a series of questions are asked of the patient to determine likes and dislikes as well as allergies etc. The menu plan is fixed with alternates available for main entrée dishes as well as some juices and other easy food items. The patient never fills in a menu card. The system chooses what the patient gets based on likes and dislikes. An example – the patient says they do not like Tomato Sauce and Apple Juice – and on Tuesday the menu says that Breakfast is Scrambled egg, Muffin, and Apple Juice…they will be given an orange juice instead. At lunch the menu says that a Lasagne will be served and seeing the patient does not like Lasgane they will receive an alternate which that day is a Tuna Sandwich. The majority of cold plating locations use this system and it is predominant in ‘regional food service models’ where large numbers of patients are served from one central location. Menus are often developed for 2 week cycles however we are seeing more and more 7 day menu cycles emerging. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day.

Spoken Menu – There are two versions that we see of Spoken Menu here in Canada. The first is the use of a mobile trolley that has a combination of bulk and portioned foods which is taken throughout a ward for meal service and used as a local assembly system for trays. The second is assembling trays outside the ward in a pantry or centrally in a kitchen based on a patient selection from the previous meal.

In Bulk Meal Trolley Service we see a bulk trolley of food set up outside patient rooms in the hall or at a nearby pantry – the bulk trolley is stocked with regular items such as juices, milks, condiments etc but is also stocked with other hot and cold foods that have been made for that day following a menu for the week. The server enters the patient room and verbally asks what they would like for their meal. The patient selections from the trolley are checked with patient diet orders for compliance, the tray is assembled, and the patient receives their tray within 3 minutes. This is a great system (often used in the UK ) and can drive patient satisfaction very high. Key concerns are labor to do the meal service, space at ward level, infection control procedures, and food control over waste. Good forecasting techniques must be in place to make this system a success. It can be done using bulk food trolleys or even pre-plated meal entrees. There are advantages and disadvantages to both. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day. The spoken menu can also be put into place for ambulatory patients who can eat at a dining room within the hospital.

In Tray Assembly in a pantry or central kitchen we take the order at the patient bedside at the end of a meal (say breakfast ) and using a hand held device (or a low tech solution such as a pen and paper), take the order from the patient of their next meal. The hand held then sends the info to the kitchen immediately, or, when the worker goes back to the kitchen, the order is uploaded via a sync feature. The tray can then be put together in the kitchen close to meal service and then served. Tray assembly can be cold or hot. Tray assembly utilses a new style of meal assembly at a series of work cells specially designed for tray assembly in healthcare foodservices. These B-Lean Stations will help improve efficiency and working conditions for staff.Food trays can be placed inside retherm tray carts (Novaflex or B-Pod) or, in a hot line method where the food being plated is hot, an active temperature maintenance system can be used to keep food trays at optimum temperatures while other trays are being prepared (the RTS or Ready to Serve).

Room Service – here we have the patient ordering their meals at any time of the day (within a set timeframe such as 6 am – 6 pm). They can order using touch screens or via telephone and the order from a Room Service Menu like you would find in a hotel room. The meal is brought to them within 45 mins of ordering. Here we still need a computerized diet office that will check the patient order against diet orders, track food being produced, and expedite order to various stations within the central kitchen. We normally see the Room Service Models alongside traditional cook serve with ‘a la minute’ tray assembly , however we are seeing some hybrids developing that make use of chilled or frozen foods. While this new service is intriguing and is seen as innovative and customer focused, the system is labor intensive, can be costly on food if waste occurs, and logistically can tie up the hospital in a knot it never anticipated – for example, without protected meal times, staff from the kitchen now run meals to wards throughout the entire day at unscheduled times due to patient demand and elevators can get very tied up unless the hospital has dedicated service desire lines of transport. The system can also tax staff as they work to demand which can fluctuate each day – staff normally want their jobs to be structured and like routine. In Canada, we see Room Service emerging for special populations such as OBS (Maternity) or Rehab. It is not a system to put in place in surgical wards – who will call the order down ?

There are a number of other ‘hybrid’ type models that can be cited but the aforementioned does cover the majority. The hybrids take one of the above and tweak it normally because of site conditions such as patient population types, physical structure, capital available, nursing responsibilities at ward level, program management approaches etc. I think if there is a need of further insight into this, you should connect with CBORD, VISION, COMPUTRITION or another diet office software supplier who I am sure would give you a great historical review as well as what is available now and what is coming .

Comments Off on Patient Food Ordering Methods Practiced in Canadian Hospitals

Many facility managers are either serving a Continental Breakfast or considering to do so. In many cases they are investigating the idea of ward based assembly of a continental breakfast. To that end, Burlodge has reached out to its European counterparts to see what ideas they have embraced since continental breakfast in Europe is very common.

The array of Breakfast cart equipment in Europe is extensive to say the least, but it has taken years to reach a point where there is finally a cart available that meets the needs of the many rather than the few. This cart from Burlodge, called the Breakfast Beverage Cart, has been designed after two years of listening and testing. The cart is now available in North America.

Intriguing is the fact that the cart can also act as a simple beverage cart during in-between meal times or if a continental breakfast service is not offered. A hydration program is a very important aspect of nutritional care for the sick. In Europe hydration plays a major role in the healthcare sector’s wellness mandate.

“…there is nothing yet discovered which is a substitute to the English patient for his cup of tea…” Florence Nightingale, Notes on Nursing, 1859

According to the British Dietetic Association ‘ Attending to the patients’ fluid needs is an essential aspect of care. Many patients may be dehydrated, having raised body temperatures and in warm ward settings. Drinks should be accessible to the patient, served at an acceptable temperature, and in suitable and appealing cups, glasses or mugs. Care should be taken to avoid excessive fluid intake for those requiring a fluid restriction, as in some renal patients. The HCA Good Practice Guide (2006) recommends at offering at least 7 beverages a day with chilled water available 24 hours a day. It recommends considering water as an essential nutrient in a wholesome patient diet. In addition to tea and coffee, there should be access to fruit juices, cordials and milk based drinks as well as iced water.”

The idea of offering a beverage with a smile between meals is new to North America. It is often a ‘help yourself’ process for many patients who walk to a ward pantry and get a drink or perhaps they are lucky to have a visitor come to the ward that brings a coffee or tea during visiting hours. To offer a hot coffee or comforting tea at the bedside during mid-afternoon would mean more patient contact and it is that face time and direct patient care approach that will drive satisfaction to new heights. Some pundits may say that this is an increase in cost that the healthcare sector cannot afford or sustain. There are, however opportunities to find major discounts on ingredients from the manufacturing sector if the hospital features a specific brand of tea or coffee. There are opportunities to fund the labor and cost of this effort by ‘leaning’ other areas of the operation thereby reallocating work and cost from indirect non value adding areas of foodservice. The question is now asked and it is up to the courageous to find a way to make it work.

The idea of offering a beverage with a smile between meals is new to North America. It is often a ‘help yourself’ process for many patients who walk to a ward pantry and get a drink or perhaps they are lucky to have a visitor come to the ward that brings a coffee or tea during visiting hours. To offer a hot coffee or comforting tea at the bedside during mid-afternoon would mean more patient contact and it is that face time and direct patient care approach that will drive satisfaction to new heights. Some pundits may say that this is an increase in cost that the healthcare sector cannot afford or sustain. There are, however opportunities to find major discounts on ingredients from the manufacturing sector if the hospital features a specific brand of tea or coffee. There are opportunities to fund the labor and cost of this effort by ‘leaning’ other areas of the operation thereby reallocating work and cost from indirect non value adding areas of foodservice. The question is now asked and it is up to the courageous to find a way to make it work.

If, for example, a hospital has 6 floors and on each floor there are 30 patients and it would take 3 minutes to ask, pour, and serve each patient, a floor could be served in 90 minutes by 1 person. If that person could then go and serve another floor a full beverage service mid-afternoon could be completed within 3 hours between lunch and dinner. For the entire hospital one would need 3 staff to do this. This works out to be 1.68 productive Full Time Equivalent positions and where on earth could that staffing come from? It begs some important questions:

At Burlodge, we believe that there are ways of finding answers to these questions, making this service a reality. It only means taking the time to look and catch a dream.

Another source to fund a beverage service may actually come from the implementation of a continental breakfast or the implantation of more advance meal delivery equipment that can help reduce the resources associated with meal tray holding, transport, cleaning.

References: Guidance on hydration

• Food, Fluid and Nutritional Care in Hospitals (NHS Quality Improvement Scotland,2003).

• Good Practice Guide Healthcare Food and Beverage Service Standards Section 4 (HCA, 2006)

• Water UK e.g. ‘Water for Healthy Ageing’ (Water UK, 2006 [online])

• Water for Health Alliance www.waterforhealth.org.uk

• Water for Health Alliance Bulletins available via www.hospitalcaterers.org

Manufactured entirely in stainless steel, the BBC (Breakfast & Beverage Cart) has an on-board boiler with the capacity to serve 90 cups (15 litres) of hot drinks.

The mobile service system has multiple drawers for holding baskets, hotel pans, or ingredient containers making it easy to obtain items during service. China can be carried on-board in three standard 500mm square cup baskets.

The integrated Toast warming cabinet keeps a breakfast tradition on your menu.

FEATURES

Comments Off on Ideas for Improved Patient Satisfaction and Wellness

The following are some key points of difference between standard Pod style equipment set-ups and the Burlodge B-Lean Program:

1. Burlodge’s B-Lean is a system. It is not just equipment. Burlodge has an expert team of operators who assist with the various stages of successful implementation. Burlodge’s team help with staff presentations regarding change management. They offer assistance in menu review to lean the number of menu items to make the work cells more efficient. They assist with equipment placement and layout to make the most out of the available space and flow. They help with pre-start up and actual start-up training and support and are often on site for a full week during the actual start up. They assist with post start-up services such as metric calculations to see if the TAKT time forecast is actually being met, if the lines are balanced, and if proper ergonomics are in place. They provide annual operational reviews. All of this is done at no extra charge to the client and is part of the B-Lean commitment.

2. Burlodge’s B-Lean Gravity Shelves accommodate labels for foods. Labels can be prepared in advance and they can slide into the front of the shelf to denote the row names/categories.

3. The Burlodge B-Lean Gravity Shelves can be filled from the rear allowing the tray assembly process to continue without stoppages.

4. The B-Lean equipment includes an innovative tray assembly table that uses teflon slides to allow free movement of a tray along its path to completion. It is a non-motorized tray table but trays slide with ease with a gentle push to the right or left. The tray table is open in the middle allowing the operator to reach down in fron of or behind the tray to access food items or cutlery below. This makes use of every space in front of the worker. The tray table fits under the gravity fed shelving system so that the shelves actually hang over the table making the reach for the worker as natural as possible. All tray tables are mobile and have shelves for added storage below. The long tray table can be used by itself or it can be parked alongside a shorter tray table when tray assembly requires more staff or when there are more items to place on trays. Either way, the entire concept is to allow for the greatest flexibility in work flow and use of space.

5. Burlodge’s B-Lean equipment can be refrigerated. This includes the Gravity Shelf (ALPHACOOL) and this equipment has rear side access so as not to stop the assembly line while re-filling/replenishing. The ALPHACOOL Air Curtain Gravity Shelf is one of a kind in the market and has an optional removable rack in case the facility wishes to pre-assemble a gravity rack ahead of a meal service only to roll out the rack from before and replace it with a new, completely filled and ready rack for the next meal service. The Tray Assembly table can be refrigerated and this can hold key food safe items in the wells between the tray slides on a spring lowerator and inside baskets. The staff only have to reach in to get what they need.

6. Burlodge’s B-Lean is completely mobile allowing the staff to remove or add pieces as they wish depending on meal volume or complexity of tray assembly (breakfast may require less equipment than lunch/dinner). The complete modular system allows a facility to be reactive to each meal’s needs and yet it represents a proactive capital purchase as the future demands will never be constraining (the B-Lean equipment can be expanded and/or contracted easily)

7. Burlodge’s B-Lean has been ergonomically tested and continues to go through ergonomic assessments to ensure infrequent twisting and bending of staff. All items are within an effective reach distance for the staff.

8. Burlodge’s B-Lean system incorporates the use of Gravity Shelves which again is a unique difference compared to slanted bins or angled trays. The gravity shelves can be adjusted in slope to accommodate different food product weights and packaging (i.e. to give the best slide effect possible to guarantee product items are always at the same position for reaching).

9. The Burlodge B-Lean System comes complete with a comprehensive training and operational manual and supportive poster boards for staff education prior to start up (advertising and managing the message before equipment arrives).

10. The Burlodge B-Lean System incorporates Lean Principles which can in the end help transform the entire department to a more efficient and lean operation.

11. The Burlodge B-Lean System is the only one of its kind that offers mass hot beverage re-heat of portioned coffee/tea. This helps speed the assembly process while always guaranteeing a hot beverage is provided at every meal.

1. Conventional Ordering Method – while slowly becoming an archaic method, we do still see cases of passing meal plans ( a daily menu selection sheet) to patients for them or family members to select meal components for breakfast, lunch, dinner. They do this using a sheet of paper with the menu printed on it, a pen, and circle the things they want following strict guidelines as noted on the paper. They often do this about 2 days in advance of the actual menu day they are selecting. Of course, this system has its many disadvantages such as and not limited to:

– poor control as patients may actually not be at the hospital two days after they fill in their sheet

– manual and labor intense system for the diet office

– poor control over diet therapy as many mistakes can happen

– patient forgets what they selected and this can lead to poor satisfaction ratings overall

– high food cost due to waste through poor forecasting methods

– diet changes are manual and thus more labor wasted to track and correct menu plans

This system is often applicable to hot serve locations and can be developed using a long cyclical menu of up to 3 weeks. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day.

2. Selective Menus but Modernized – the patient selects their meal by using a daily menu planner as above, but the information is then inputted into a computer and the diet office then uses a computer software program such as CBORD or COMPUTRITION to tally and talk to production as well as trayline. Proper tray tickets are printed according to the beltline set up and diet therapy integrity checks are done within the software so that patient selections match diet orders. This system is most common now at facilities that are still hot plating although we do see this at cold plating locations. It is still manually intensive and patients may choose meals the day before so there is still a loss of control by the patient which can impact satisfaction. Menus are often developed in 2 week cycles. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day. We are seeing a small resurgence of the selective menu through the use of technology whereby patients can select what they want during a bedside interview by a diet tech or food service worker who enters selections into a palm device but this is rare at the moment.

3. Non Selective Menus – here we have the use of a computer software system like mentioned above. The system integrates with the hospital’s ADT System (admission, Discharge, Transfer) and thus keeps tabs on who is in the house and who is not. In addition, the system will connect with the hospital patient record info and inform the dietary department when a diet change has been ordered. The intriguing thing about this system is that it is built on the premise that the patient preferences are determined at admission. Here, a series of questions are asked of the patient to determine likes and dislikes as well as allergies etc. The menu plan is fixed with alternates available for main entrée dishes as well as some juices and other easy food items. The patient never fills in a menu card. The system chooses what the patient gets based on likes and dislikes. An example – the patient says they do not like Tomato Sauce and Apple Juice – and on Tuesday the menu says that Breakfast is Scrambled egg, Muffin, and Apple Juice…they will be given an orange juice instead. At lunch the menu says that a Lasagne will be served and seeing the patient does not like Lasgane they will receive an alternate which that day is a Tuna Sandwich. The majority of cold plating locations use this system and it is predominant in ‘regional food service models’ where large numbers of patients are served from one central location. Menus are often developed for 2 week cycles however we are seeing more and more 7 day menu cycles emerging. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day.

4. Spoken Menu – There are two versions that we see of Spoken Menu here in Canada. The first is the use of a mobile trolley that has a combination of bulk and portioned foods which is taken throughout a ward for meal service and used as a local assembly system for trays. The second is assembling trays outside the ward in a pantry or centrally in a kitchen based on a patient selection from the previous meal.

In Bulk Meal Trolley Service we see a bulk trolley of food set up outside patient rooms in the hall or at a nearby pantry – the bulk trolley is stocked with regular items such as juices, milks, condiments etc but is also stocked with other hot and cold foods that have been made for that day following a menu for the week. The server enters the patient room and verbally asks what they would like for their meal. The patient selections from the trolley are checked with patient diet orders for compliance, the tray is assembled, and the patient receives their tray within 3 minutes. This is a great system (often used in the UK ) and can drive patient satisfaction very high. Key concerns are labor to do the meal service, space at ward level, infection control procedures, and food control over waste. Good forecasting techniques must be in place to make this system a success. It can be done using bulk food trolleys or even pre-plated meal entrees. There are advantages and disadvantages to both. Meal service times are what we call ‘protected’ and thus happen at regularly scheduled times throughout the day – this helps with production logistics as well as keeps the unit level ward staff happy that they follow a set schedule of activity each day. The spoken menu can also be put into place for ambulatory patients who can eat at a dining room within the hospital.

In Tray Assembly in a pantry or central kitchen we take the order at the patient bedside at the end of a meal (say breakfast ) and using a hand held device (or a low tech solution such as a pen and paper), take the order from the patient of their next meal. The hand held then sends the info to the kitchen immediately, or, when the worker goes back to the kitchen, the order is uploaded via a sync feature. The tray can then be put together in the kitchen close to meal service and then served. Tray assembly can be cold or hot. Tray assembly utilses a new style of meal assembly at a series of work cells specially designed for tray assembly in healthcare foodservices. These B-Lean Stations will help improve efficiency and working conditions for staff.Food trays can be placed inside retherm tray carts (Novaflex or B-Pod) or, in a hot line method where the food being plated is hot, an active temperature maintenance system can be used to keep food trays at optimum temperatures while other trays are being prepared (the RTS or Ready to Serve).

5. Room Service – here we have the patient ordering their meals at any time of the day (within a set timeframe such as 6 am – 6 pm). They can order using touch screens or via telephone and the order from a Room Service Menu like you would find in a hotel room. The meal is brought to them within 45 mins of ordering. Here we still need a computerized diet office that will check the patient order against diet orders, track food being produced, and expedite order to various stations within the central kitchen. We normally see the Room Service Models alongside traditional cook serve with ‘a la minute’ tray assembly , however we are seeing some hybrids developing that make use of chilled or frozen foods. While this new service is intriguing and is seen as innovative and customer focused, the system is labor intensive, can be costly on food if waste occurs, and logistically can tie up the hospital in a knot it never anticipated – for example, without protected meal times, staff from the kitchen now run meals to wards throughout the entire day at unscheduled times due to patient demand and elevators can get very tied up unless the hospital has dedicated service desire lines of transport. The system can also tax staff as they work to demand which can fluctuate each day – staff normally want their jobs to be structured and like routine. In Canada, we see Room Service emerging for special populations such as OBS (Maternity) or Rehab. It is not a system to put in place in surgical wards – who will call the order down ?

There are a number of other ‘hybrid’ type models that can be cited but the aforementioned does cover the majority. The hybrids take one of the above and tweak it normally because of site conditions such as patient population types, physical structure, capital available, nursing responsibilities at ward level, program management approaches etc. I think if there is a need of further insight into this, you should connect with CBORD, VISION, COMPUTRITION or another diet office software supplier who I am sure would give you a great historical review as well as what is available now and what is coming.

Comments Off on Patient Food Ordering Methods