Value Stream Mapping (VSM) Overview

It is important for every organization to recognize its current position or state before embracing the concept and principles of Lean Thinking. Value stream mapping (VSM) is a core tool of Lean and is invaluable in conducting bottom-up studies while concurrently progressing up to the higher-level organizational systems that support these.

While Lean is effectively a business philosophy dedicated to the elimination of waste and built on five major principles: customer value (focus), value analysis, flow, pull and the pursuit of perfection, VSM provides the techniques required to document and improve the entire system, including both information and material flows. This combined approach can be applied to almost any supply chain, manufacturing or administrative process and is most effective when carried out throughout the entire organization.

VSM enables an organization to understand its current supply chain process. VSM visually maps what the company is currently doing and achieving (as opposed to what the organization thinks it is achieving) and from that map the company can create a future state map or vision, this end-to-end process shows the company how to operate in order to achieve the most benefits. This map of activities and information-flow provides a framework and impetus for implementing Lean.

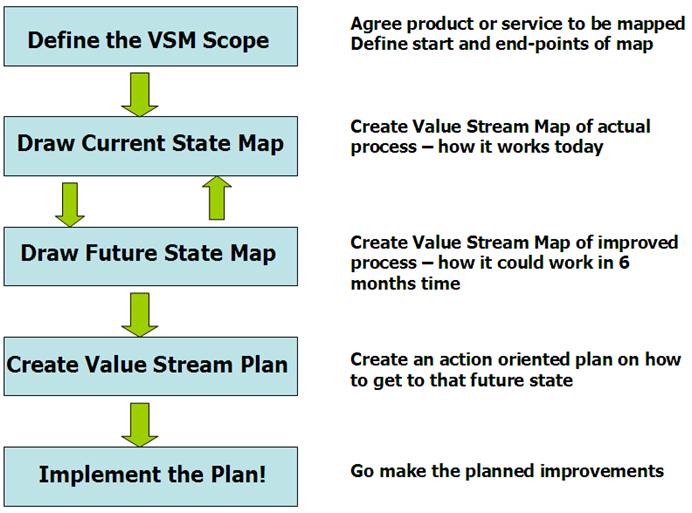

The steps in implementing VSM:

This article was provided by Leading Edge Group